Using a precision scale in your DIY projects boosts safety by ensuring you measure ingredients, chemicals, or components accurately, reducing errors and potential hazards. It helps you achieve consistency, especially when working with delicate or hazardous materials. Proper setup, calibration, and maintenance are key for reliable results. If you want to know how this upgrade can make your DIY safer and improve your projects, keep going to discover more helpful tips.

Key Takeaways

- Accurate measurements reduce errors, ensuring safer chemical handling and electrical wiring in DIY projects.

- Proper calibration and maintenance prevent measurement inaccuracies that could lead to unsafe outcomes.

- Precise weight data helps avoid overloading components, reducing fire hazards and mechanical failures.

- Using certified calibration weights and stable placement enhances measurement reliability and safety.

- Consistent, precise measurements improve overall project quality, minimizing risks and ensuring safe results.

What Are Precision Scales and Why They Matter for DIY Projects

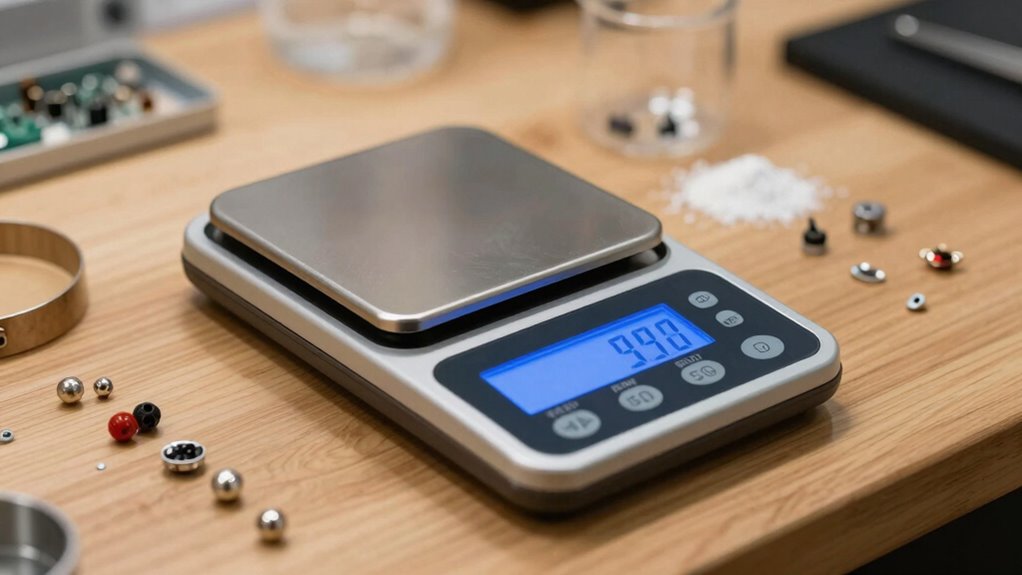

Have you ever needed to measure tiny amounts of ingredients or components with absolute accuracy? Precision scales are designed for this purpose. These scales provide highly accurate measurements, often down to fractions of a gram or milligram, essential for detailed DIY projects. Proper scale maintenance guarantees consistent performance, preventing errors caused by dust, dirt, or mechanical issues. Understanding measurement units is vital—whether grams, milligrams, or ounces—so you can choose the right scale for your needs. measurement units are fundamental to ensure you interpret the results correctly, especially when working with sensitive materials. Precision scales eliminate guesswork, helping you achieve reliable results every time. They’re especially valuable when working with delicate materials or recipes that require exact proportions. Regularly calibrating your scale is crucial to maintain measurement accuracy over time. Additionally, choosing a reliable power source can enhance your scale’s performance and longevity. With the right scale and proper care, your DIY projects will be safer, more precise, and ultimately more successful.

Do You Really Need a Precision Scale for Your DIY Work?

Deciding whether you need a precision scale depends on the complexity and accuracy required for your DIY projects. If your work involves small components, chemical mixtures, or precise measurements, a scale guarantees measurement accuracy and consistency. Without one, you risk errors that could compromise safety or quality. However, if your projects are more casual or don’t demand exact measurements, a less precise tool might suffice. Keep in mind that regular scale maintenance is essential to maintain measurement accuracy over time. Calibration and proper storage prevent drift and ensure reliable results. Proper scale calibration techniques are vital for maintaining ongoing accuracy and should be performed routinely. Additionally, understanding the different vacuum features to consider can help you select the best tools for your specific needs. Incorporating proper calibration techniques can further improve your measurements and ensure ongoing accuracy. Regularly monitoring your scale’s performance can help detect and correct any measurement deviations early, maintaining your project’s integrity. Being aware of environmental factors like humidity and temperature can also influence weighing precision and should be managed accordingly.

How to Choose the Best Precision Scale for DIY Projects

Choosing the best precision scale for your DIY projects starts with understanding your specific measurement needs. Consider the required accuracy and maximum weight capacity to avoid overspending on features you’ll rarely use. Look for a scale with reliable scale maintenance; easy calibration and sturdy build ensure consistent performance. Regularly checking calibration procedures helps maintain measurement accuracy over time, which is essential for safety and precision. Battery life is also vital—long-lasting batteries mean fewer interruptions during your projects. Check if the scale offers auto-off features to conserve power, and consider models with rechargeable batteries for added convenience. Think about the display quality; a clear, easy-to-read screen helps prevent errors. By evaluating these factors—measurement precision, scale maintenance, and battery life—you’ll select a precision scale that’s both efficient and dependable, making your DIY work safer and more accurate. Additionally, understanding astrological influences can sometimes provide insight into your personal traits that might affect your approach to DIY projects. Paying attention to calibration procedures ensures your measurements stay accurate over time, further enhancing safety and reliability. Proper scale placement on a stable surface also contributes to more accurate readings and safer handling during your tasks.

Setting Up and Calibrating Your Scale for Accurate Measurements

To get accurate readings, you need to set up your scale correctly by placing it on a stable, flat surface. Next, follow the calibration procedures provided by the manufacturer to guarantee precision. Proper placement and calibration are key to reliable measurements every time. Additionally, ensuring the proper maintenance of your scale helps maintain its accuracy over time. Regularly cleaning and inspecting the device can prevent buildup and mechanical issues that may affect measurement accuracy. It is also important to keep the scale away from external influences like vibrations or electromagnetic interference, which can disrupt readings. Maintaining an appropriate environment by minimizing external disturbances can further improve your scale’s performance.

Proper Placement Techniques

Ensuring your scale is properly placed and calibrated is essential for obtaining accurate measurements. Start by choosing a stable, level surface free from vibrations or drafts, as uneven surfaces can affect measurement placement. Clear the area of clutter to prevent accidental knocks or interference. When positioning your scale, make sure it’s centered and at eye level for easy reading. Avoid placing it near heat sources, windows, or airflow that can cause temperature fluctuations or air currents, which impact measurement placement. Check that the scale is flat and stable before use. Proper scale positioning ensures consistent results and prevents errors. Additionally, understanding the impact of contrast ratio on image quality can help you select the best projector for your needs, ensuring your home cinema setup is both safe and effective. Taking these steps guarantees your measurements are reliable, making your DIY projects safer and more precise. Regularly calibrating your scale using calibration weights further enhances measurement accuracy and reliability, helping to mitigate potential measurement errors. Maintaining awareness of proper placement techniques can also extend the lifespan of your scale and improve overall measurement consistency.

Calibration Procedures

After placing your scale on a stable, level surface and clearing the area of clutter, the next step is to calibrate it to guarantee accurate measurements. Proper calibration guarantees correct weight distribution readings and maintains reliability over time. To do this effectively, regularly check and adjust your scale according to the manufacturer’s instructions. Keep in mind that calibration frequency depends on how often you use it and the environment’s conditions. Additionally, understanding maximizing your truck bed’s potential can help you determine the appropriate calibration practices for your specific setup. Here are key tips:

- Use certified calibration weights for accuracy

- Zero your scale before each calibration

- Avoid sudden weight shifts during calibration

- Record calibration dates for maintenance

- Recalibrate if you notice inconsistent readings

- Recognize the importance of consistent measurement practices in maintaining scale accuracy

Following these steps ensures your scale remains precise and dependable for all your DIY projects.

Which DIY Projects Benefit Most From Precise Measurements

If you enjoy baking or cooking, precise measurements help guarantee your recipes turn out just right. When working on electrical or wiring projects, accuracy prevents errors and safety hazards. These DIY projects benefit the most from using a precision scale to achieve reliable, professional results. Utilizing Smart Home Technology such as connected sensors and automation can also enhance safety and efficiency during these tasks. Incorporating accurate measurement tools ensures your work meets safety standards and improves overall project quality.

Baking and Cooking Precision

Have you ever noticed how a slight difference in ingredient measurements can change the outcome of your baked goods or dishes? Precise measurements are essential in baking and cooking, where weight accuracy directly influences texture, flavor, and appearance. Using a precision scale helps guarantee measurement consistency, so each batch turns out just right. Whether you’re making bread, pastries, or sauces, accurate weight measurements prevent mistakes and improve results. The benefits include better control over ingredient proportions, reduced waste, and more predictable outcomes. With a reliable scale, you can confidently follow recipes or experiment with new ones, knowing your measurements are spot-on. For any serious home cook or baker, investing in a precision scale elevates your culinary craft and minimizes errors.

Electrical and Wiring Accuracy

Wondering which DIY projects demand the highest level of electrical and wiring accuracy? If you’re working on battery maintenance or installing complex electrical systems, precision is vital. Accurate measurements ensure safe, reliable connections, preventing shorts or failures. Using a precise scale helps you verify component compatibility and ensure correct wiring lengths. Proper electrical and wiring accuracy also supports tool compatibility, making it easier to connect devices without errors. When you prioritize precision, you reduce risks associated with faulty wiring, which can lead to fires or damage. Whether you’re building a solar power setup or upgrading home wiring, investing in a precision scale allows you to work confidently and safely. It’s an essential tool for any project where electrical integrity and safety matter most.

Tips for Using Your Precision Scale Safely and Effectively

To guarantee accurate and safe measurements, it’s important to handle your precision scale with care and follow best practices. Always calibrate your scale regularly to ensure reliable weight measurement. Use it on a stable, level surface to prevent errors. Check material compatibility to avoid damaging your device or skewed results—some materials may react or interfere with the scale. Avoid overloading the scale beyond its maximum capacity. Keep the surface clean and free of dust or debris, which can affect accuracy. Handle your scale gently and store it in a safe place when not in use. Wearing gloves or avoiding moisture can help maintain its longevity. Proper use and maintenance will keep your precision scale functioning safely and accurately for all your DIY projects.

How Measurement Units Affect Your DIY Results

Choosing the right measurement units is essential because it directly impacts the accuracy and consistency of your DIY results. When you select the appropriate measurement units, you guarantee your measurements are precise, reducing errors in your project. Using unfamiliar or inconsistent measurement units can lead to mistakes, especially when converting between units. Unit conversions, if not done carefully, can introduce inaccuracies that affect the final outcome. For example, switching from grams to ounces without proper conversion can alter ingredient proportions or measurements. To avoid confusion, stick to a single system of measurement whenever possible. Understanding how measurement units influence your results helps you achieve better precision and avoid costly errors, making your DIY projects safer and more successful.

Troubleshooting Calibration and Accuracy Issues

Have you ever noticed your measurements seem off even after calibration? This can be frustrating, but troubleshooting can improve your scale’s weight accuracy. First, check if your scale needs proper scale maintenance—dust or debris can interfere with readings. Second, verify that the scale is on a flat, stable surface. Third, ensure you’re using the correct calibration weights and following the manufacturer’s instructions. Fourth, avoid air currents or vibrations during weighing, which can skew results. Fifth, recalibrate regularly, especially if you notice inconsistent measurements. Maintaining your scale’s accuracy involves more than initial calibration; consistent scale upkeep is key. By addressing these issues, you’ll keep your measurements precise and reliable for all your DIY projects.

Final Tips for Getting the Most From Your Precision Scale

Getting the most from your precision scale requires more than just initial setup; it involves ongoing attention to detail. Always double-check that your measurement units are correct before weighing, as using inconsistent units can lead to errors. Regularly perform calibration procedures, even if the scale seems accurate, to maintain precision. Keep your scale on a stable, vibration-free surface, and avoid drafts or temperature fluctuations that can affect readings. Handle items carefully to prevent contamination or damage, which can skew results. When weighing, tare the container first and record measurements promptly. By staying diligent with calibration procedures and confirming measurement units, you ensure your scale provides reliable, precise results every time, making your DIY projects safer and more accurate.

Frequently Asked Questions

How Often Should I Calibrate My Precision Scale for Optimal Accuracy?

You should calibrate your precision scale at least once a month for maximum accuracy. Regular calibration ensures accuracy monitoring, helping you catch any drift or errors early. If you use your scale frequently or for critical measurements, consider calibrating more often, like weekly. Always follow the manufacturer’s guidelines, and keep track of calibration dates to maintain reliable results and safety during your DIY projects.

Can I Use a Precision Scale Outdoors or in Humid Environments?

Using your precision scale outdoors or in humid environments isn’t ideal, as it’s like trying to measure with a leaky bucket. These scales aren’t weather-resistant and can be affected by moisture, leading to inaccurate readings. To keep your scale in top shape, store it in a dry, controlled environment and avoid exposing it to humidity. Proper storage precautions guarantee your measurements stay precise and reliable over time.

What Maintenance Does a Precision Scale Require Over Time?

You should regularly calibrate your precision scale, ideally every few months or as recommended by the manufacturer, to guarantee accuracy. Keep it protected from environmental factors like humidity and dust by using appropriate covers or enclosures. Maintaining a clean, dry environment helps prevent damage and keeps your scale functioning correctly. Regular calibration and environmental protection are key to extending your scale’s lifespan and ensuring precise measurements over time.

Are Digital or Analog Scales Better for DIY Projects?

Digital scales are generally better for DIY projects because their scale display is clearer and easier to read, helping you get precise measurements quickly. They often offer multiple measurement units, making your work more flexible. You can switch between grams, ounces, or other units effortlessly. Plus, digital scales tend to be more accurate and consistent, ensuring your measurements stay reliable over time, making your DIY projects safer and more efficient.

How Do I Prevent Damage to My Scale During Regular Use?

To prevent damage to your scale during regular use, focus on proper handling techniques and scale protection. Always place the scale on a flat, stable surface to avoid falls and vibrations. Handle it gently, avoiding sudden impacts or dropping objects onto the platform. Regularly clean the scale with a soft cloth and avoid exposure to moisture or extreme temperatures. These precautions help guarantee your scale stays accurate and lasts longer.

Conclusion

Using a precision scale can boost your DIY safety and accuracy markedly. Did you know that even a 0.1-gram error can impact project quality? With the right scale and proper setup, you’ll improve your results and avoid costly mistakes. Remember, consistent calibration is key. Investing in a quality precision scale isn’t just a smart upgrade—it’s a game-changer for any serious DIY enthusiast aiming for precision and safety in every project.